EcoUpgraded

The SSAB EcoUpgraded concept saves CO2 both in steel production and during the full lifetime of the end product.

The SSAB EcoUpgraded concept saves CO2 both in steel production and during the full lifetime of the end product.

Together with our customers, SSAB continuously upgrades the material and design of applications. The benefits of upgrading to high-strength steel include reduced weight, improved fuel economy and extended product lifetime – all of which significantly contribute to reducing a product’s carbon footprint.

The SSAB EcoUpgraded concept saves CO2 both in steel production and during the full lifetime of the end product.

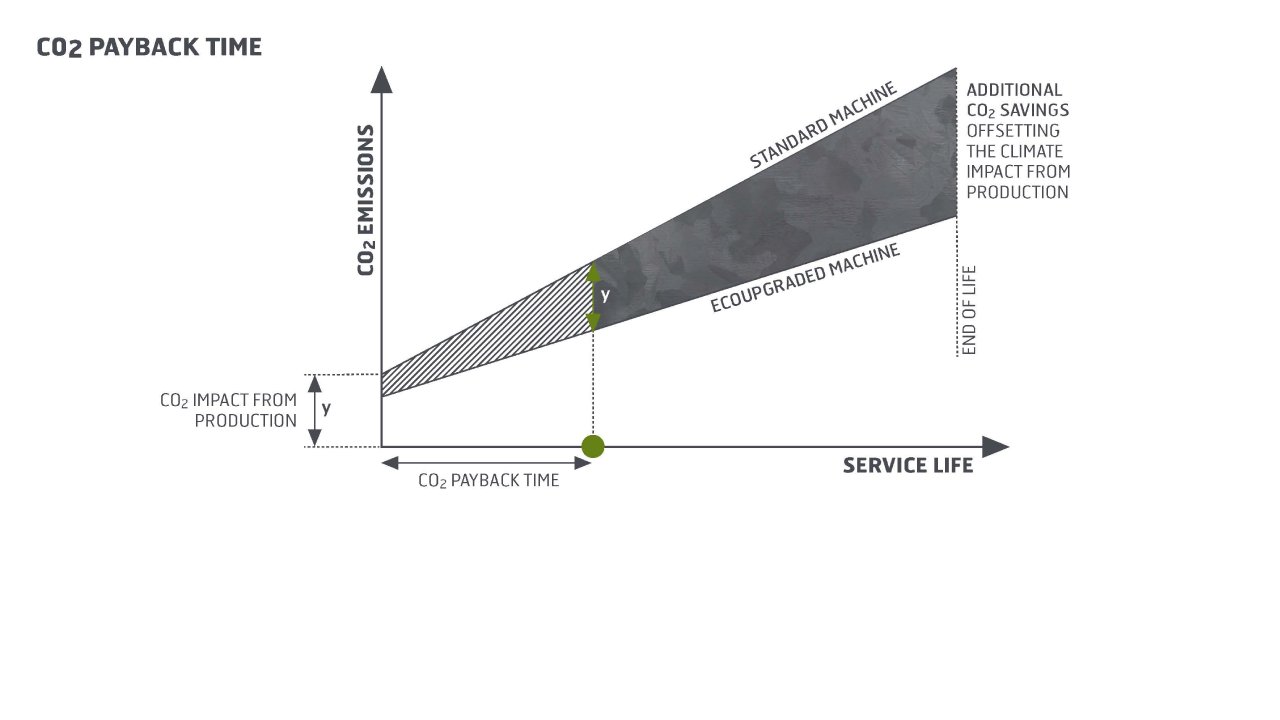

When upgrading from standard steel to SSAB high-strength steel, you can cut the weight of the end product while maintaining the same strength and increasing durability and productivity. From a life cycle perspective, this is beneficial as most of the environmental impact comes from the end product’s use phase.

In the SSAB EcoUpgraded app, you enter machine type and operational parameters. The app presents a visual report on your estimated savings.

You can save the results and share the report as PDF

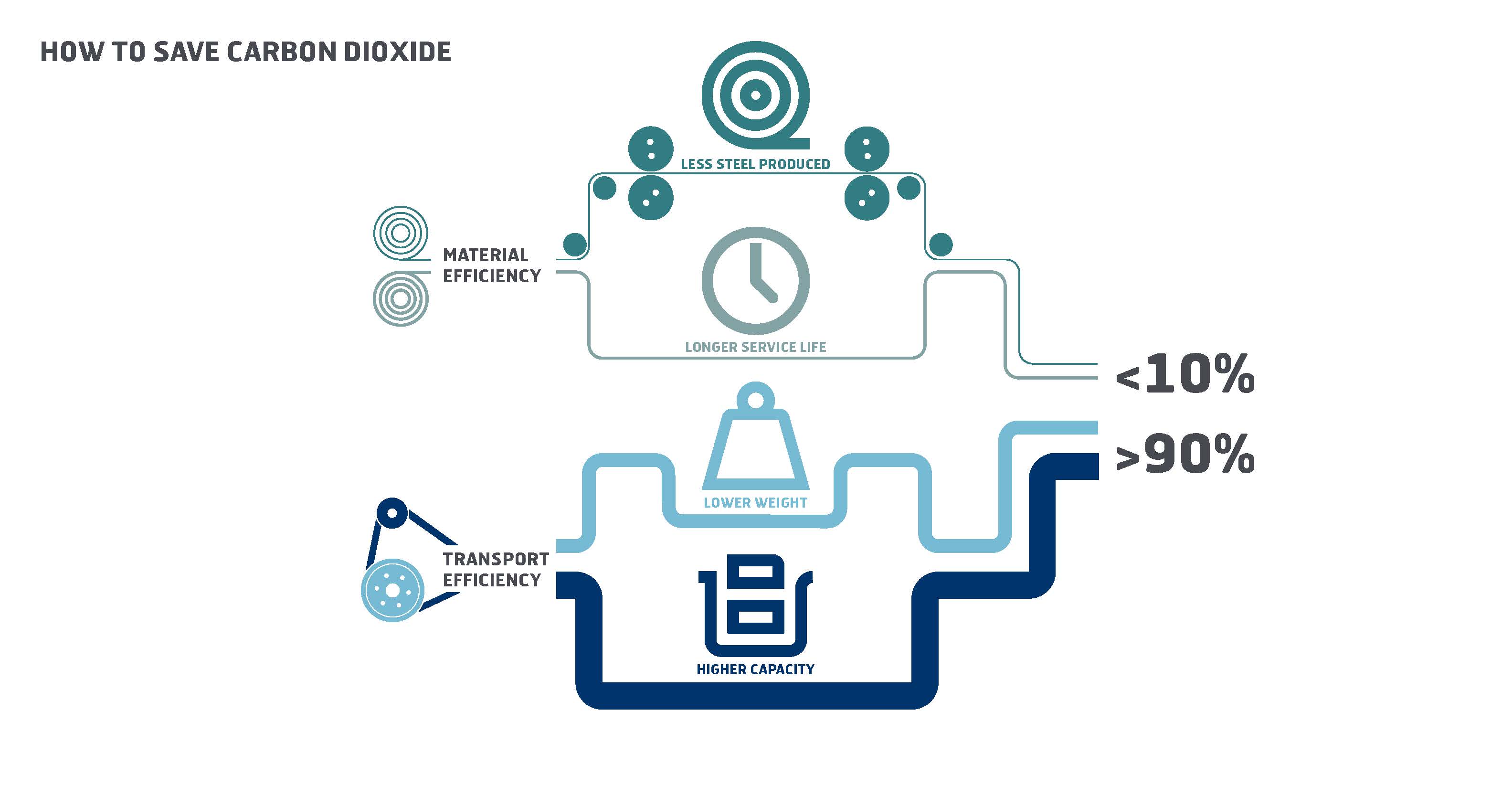

The SSAB EcoUpgraded concept helps save CO2 both in steel production and during the full lifetime of the end product. The material efficiency and transport efficiency both contribute to the CO2 savings.

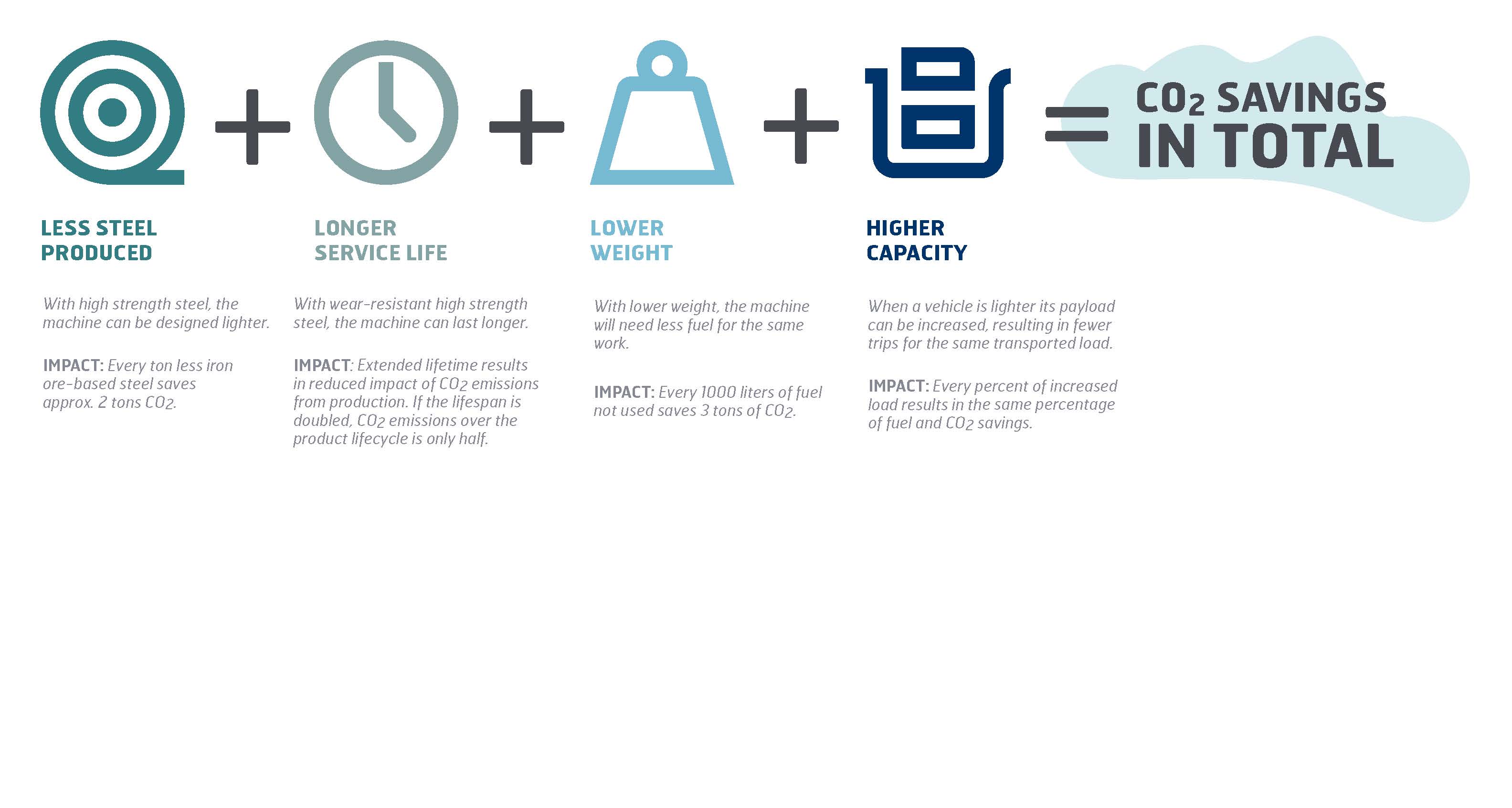

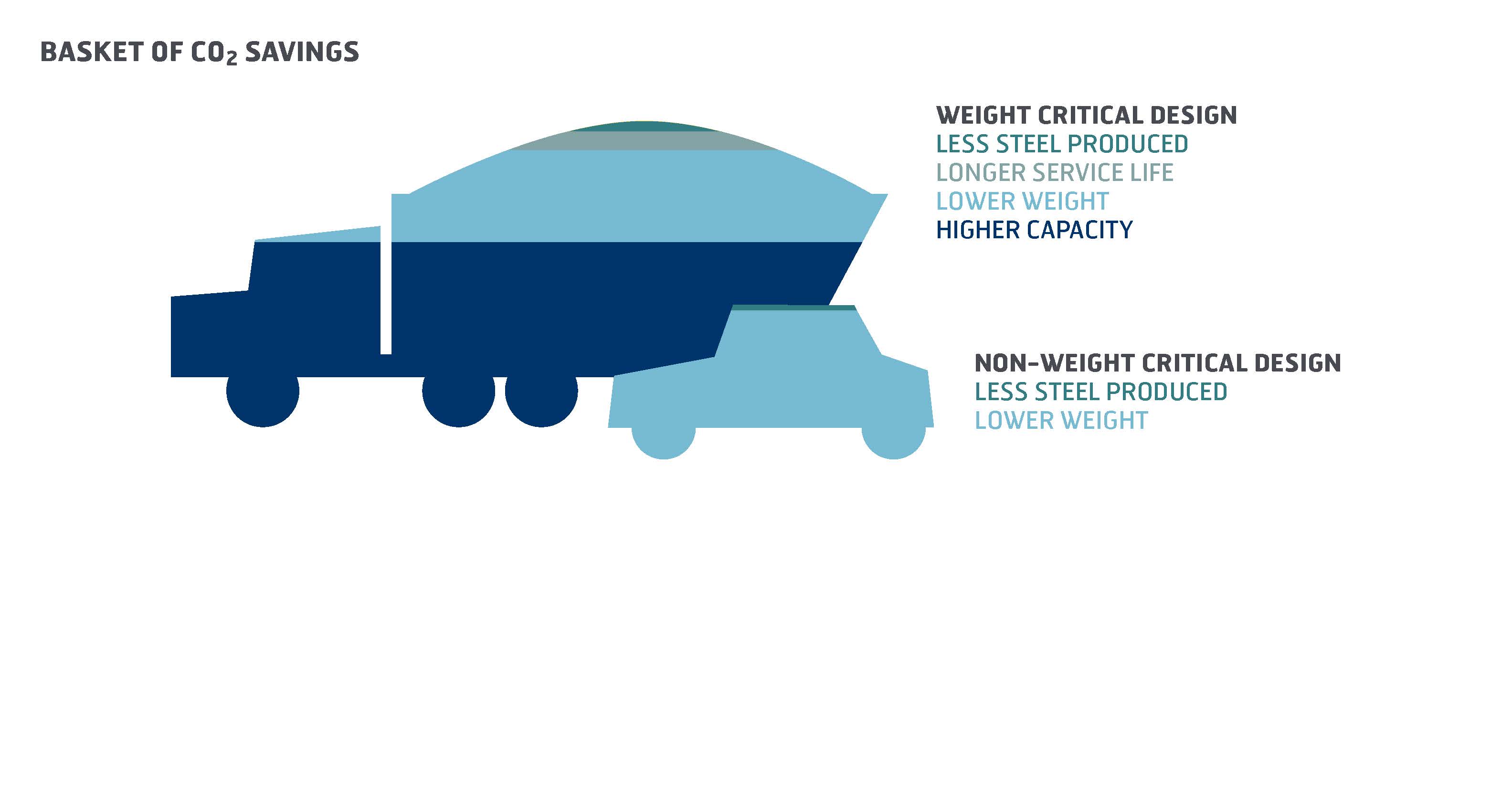

With high-strength steel, the end product can be designed lighter (less steel produced). With wear-resistant, high-strength steel, the end product also lasts longer (longer service life). With lower weight, the end product will need less fuel for the same work (lower weight). Fewer trips for the same load is the result when the reduced own weight leads to increased payload (higher capacity).

The CO2 savings differ for each application depending on whether or not the design is weight critical. In a non-weight critical design, the CO2 savings come from lower weight and less steel produced. If the weight of the design is critical, the higher capacity also contributes to the savings. In addition, the use of wear steel will contribute through a longer service life.

By upgrading with steel from SSAB, manufacturers will quickly be able to compensate for the CO2 emissions from steel production during the use of the product. And once the break-even point has been reached, the application will continue to deliver CO2 savings amounting to many times the original CO2 debt.