SSAB Form Tubes for light engineering

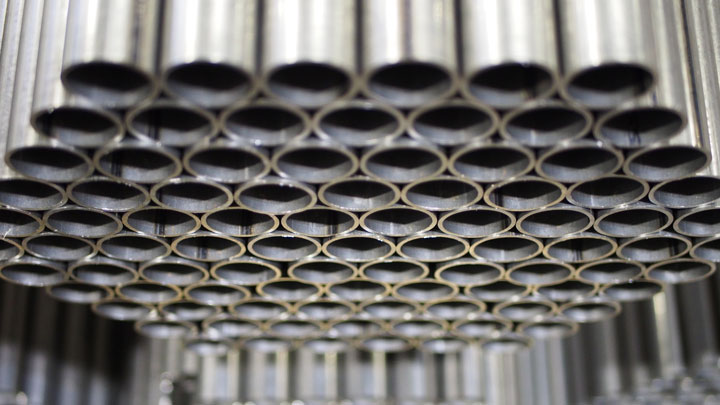

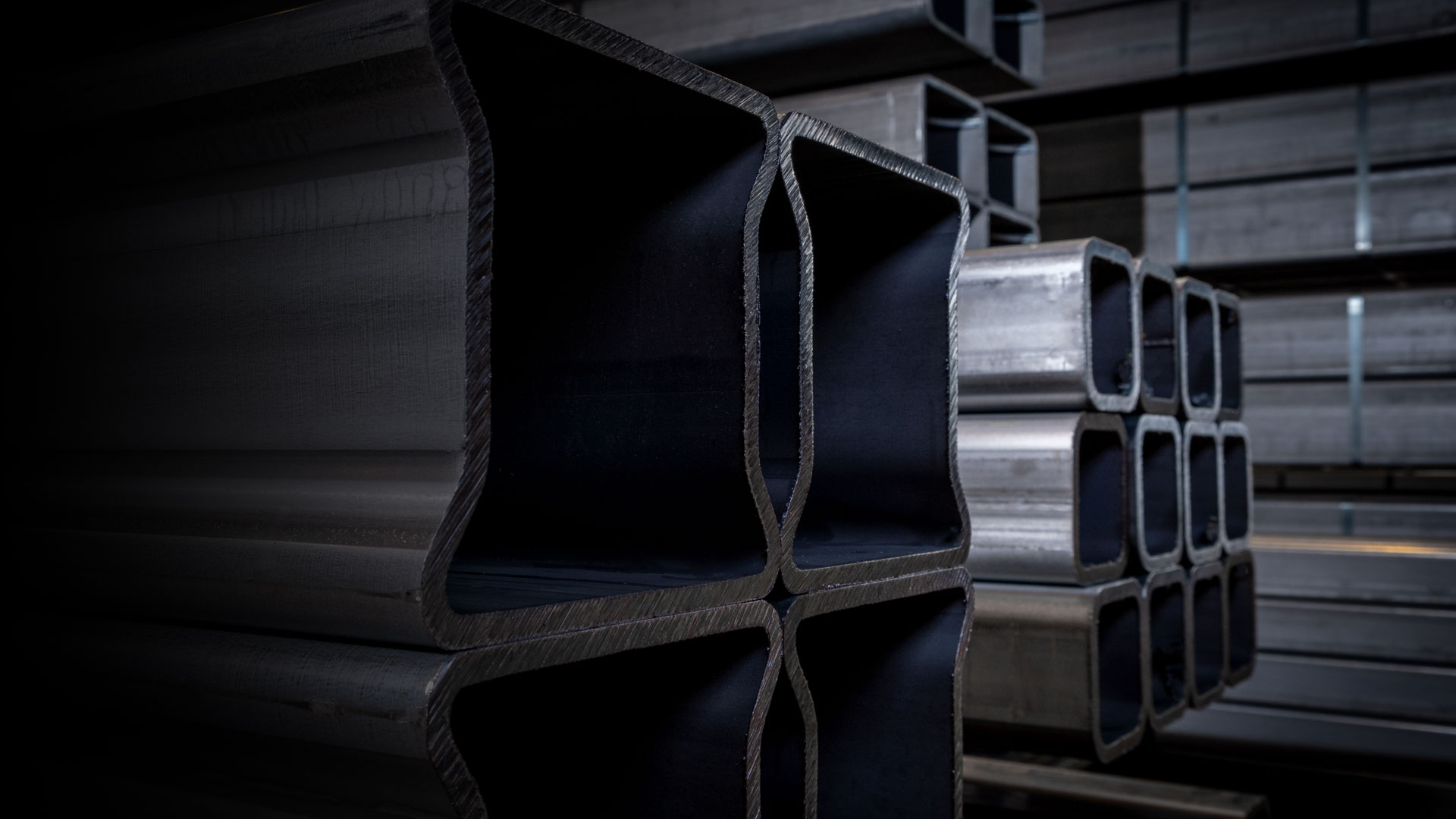

SSAB Form Tubes uniquely combine strength, formability, clean steel, and surface quality. These, thin-walled, precision tubes are available in a wide variety of standard sizes and shapes, with custom sizes, shapes and lengths available upon request. SSAB Form Tubes are used for light engineering structures, such as building safety, safety fences, furniture, store fixtures, light material handling (e.g., warehouse cage trolleys), tools, cable ladders, and fitness equipment.

The yield strength range of SSAB Form Tubes ranges from 220 MPa to 420 MPa, with tensile strengths from 310 MPa to 490 MPa. The welded, precision steel tubes are made in compliance with standard EN 10305 (parts 3 and 5) and the more demanding elongation (CR2+) values and chemical analyses. Our tubes’ outstanding elongation properties help make forming easier – increasing production reliability while giving your product more design flexibility and energy absorption. In addition, our tuned chemical composition significantly improves weldability and cutting. Plus, our tight dimensional tolerances help reduce scrap, aid robot welding, and minimize set-up and adjustment times during your production.

SSAB Form Tube 220, SSAB Form Tube 320, SSAB Form Tube 420