Customer case

Pneumatic pipe bridge using weather-resistant steels

April 17, 2023 6 min read

Case details

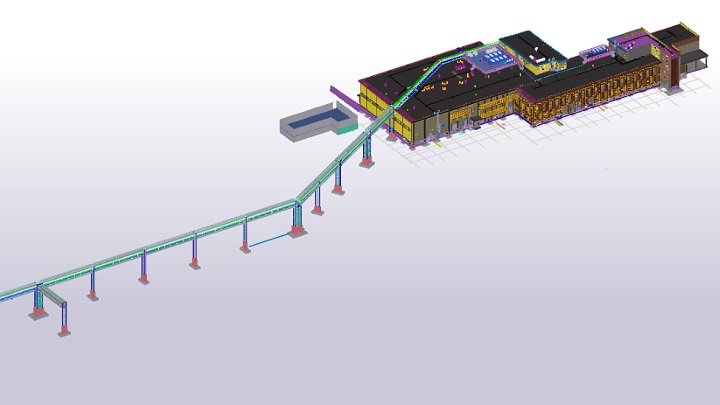

A new research center and office will be built at SSAB Europe Oy Raahe mill. The new two-story research center and office building is scheduled to be in use in 2024. In connection with the project, a new pneumatic pipe bridge will be built. The mail pipe will transport samples from the smelter and blast furnace to the new research center. About six kilometers of the new pneumatic mail pipe will be built and the old one will be upgraded. Work on construction of the pneumatic mail pipe foundation and workshop connecting the research center and the mill began in 2022 and will complete this spring.