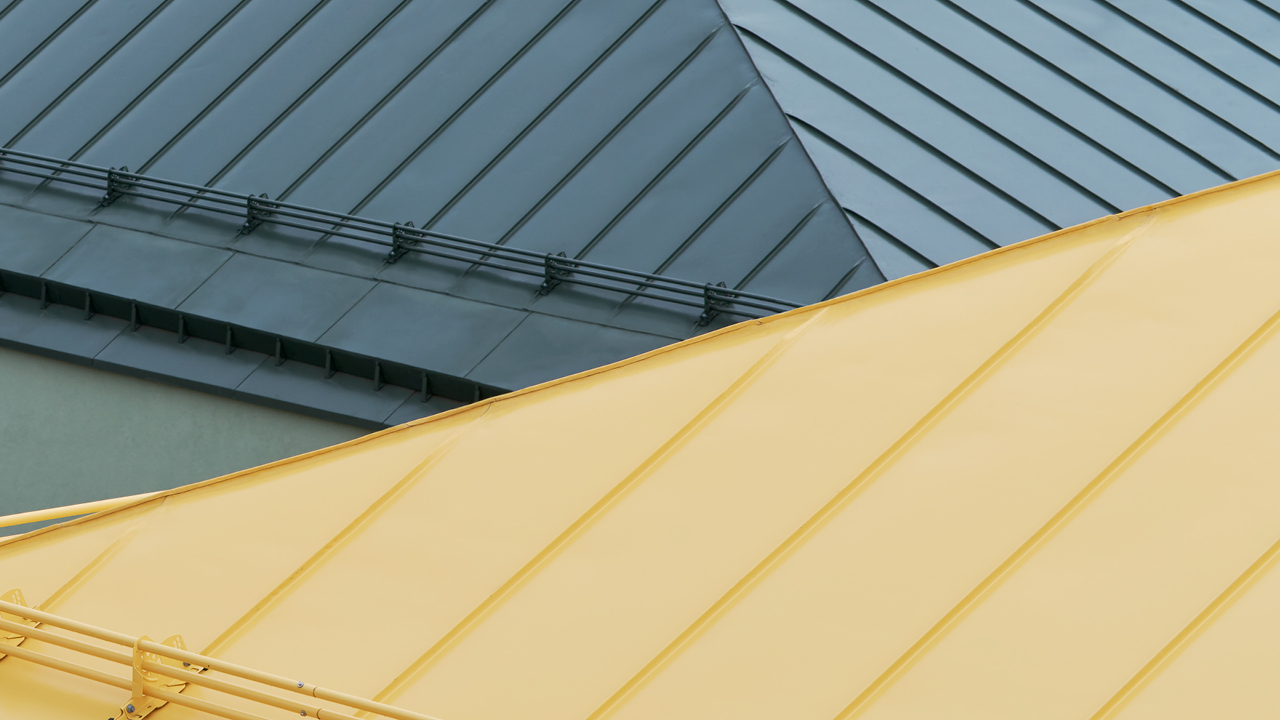

GreenCoat® color coated steel for harsh weather and greener living

GreenCoat® is the brand for innovative, sustainable color coated steel solutions for roofs, façades and rainwater systems. Widely used in sustainable architecture, GreenCoat® products offer an extensive range of colors and coatings with Swedish rapeseed oil.

Colors GreenCoat® Environmental Product Declaration (EPD)