Future-proofing your life cycle assessments

Automotive Life Cycle Assessments drive our future-proofing processes as we decarbonize the production of our advanced high-strength steels for automobiles.

Automotive Life Cycle Assessments drive our future-proofing processes as we decarbonize the production of our advanced high-strength steels for automobiles.

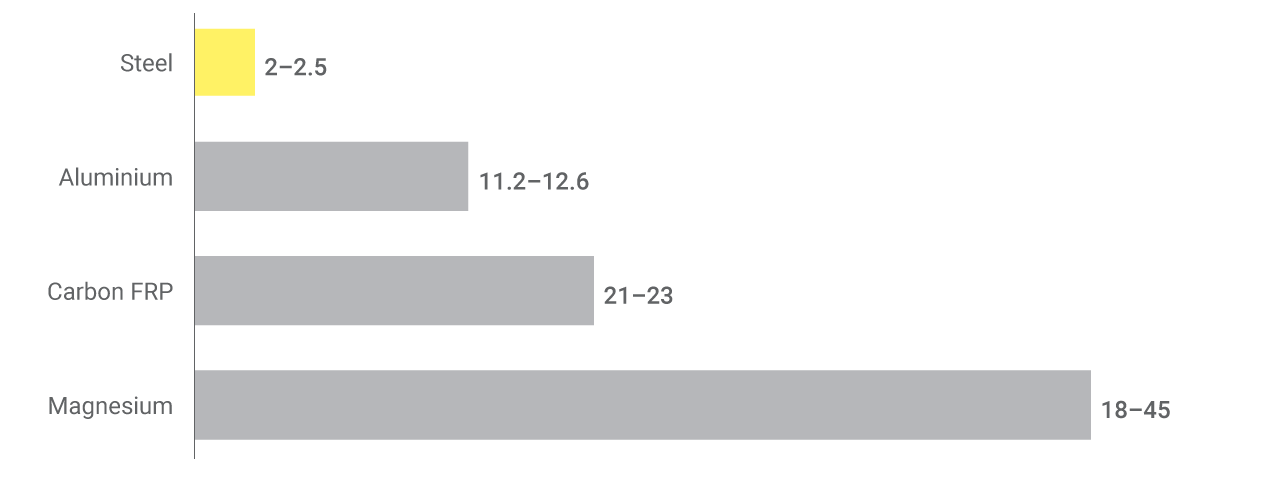

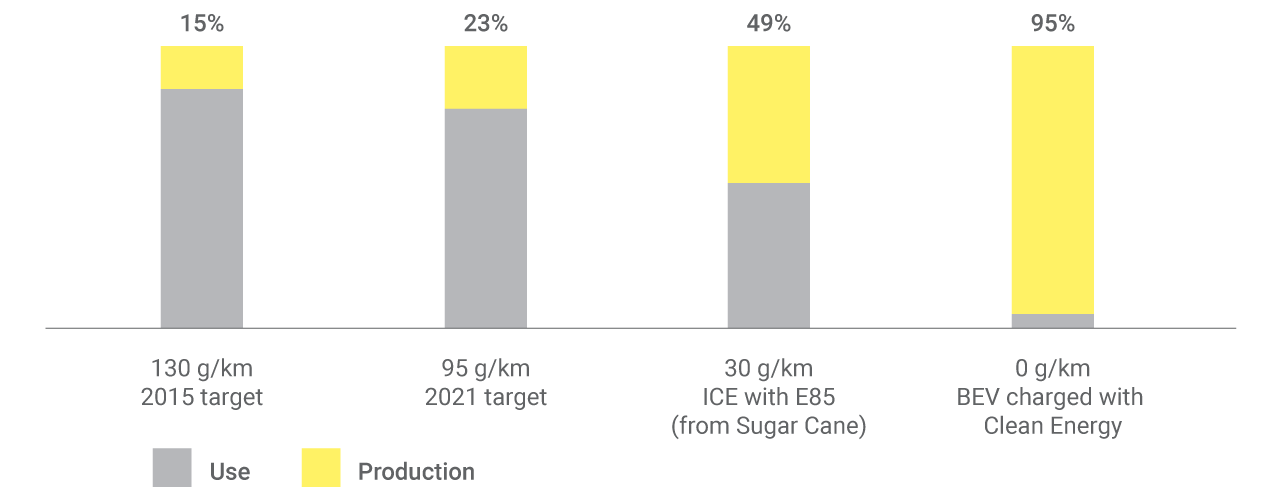

Comprehensive life cycle assessments make it impossible to reconcile that some lightweighting materials — like aluminum, carbon fiber reinforced plastics (CFRPs), and magnesium — have greenhouse gas (GHG) impacts that are many times that of Docol advanced high-strength steels.

As tailpipe emissions from car usage eventually fall to zero, the embedded carbon of your lightweight materials will undergo increasing scrutiny through automotive Life Cycle Assessments (LCAs).

Source: WorldAutoSteel.

Source: WorldAutoSteel.

The material mix has big effect on the life cycle assessment for a car. By choosing advanced high-strength steel you are off to a good start.

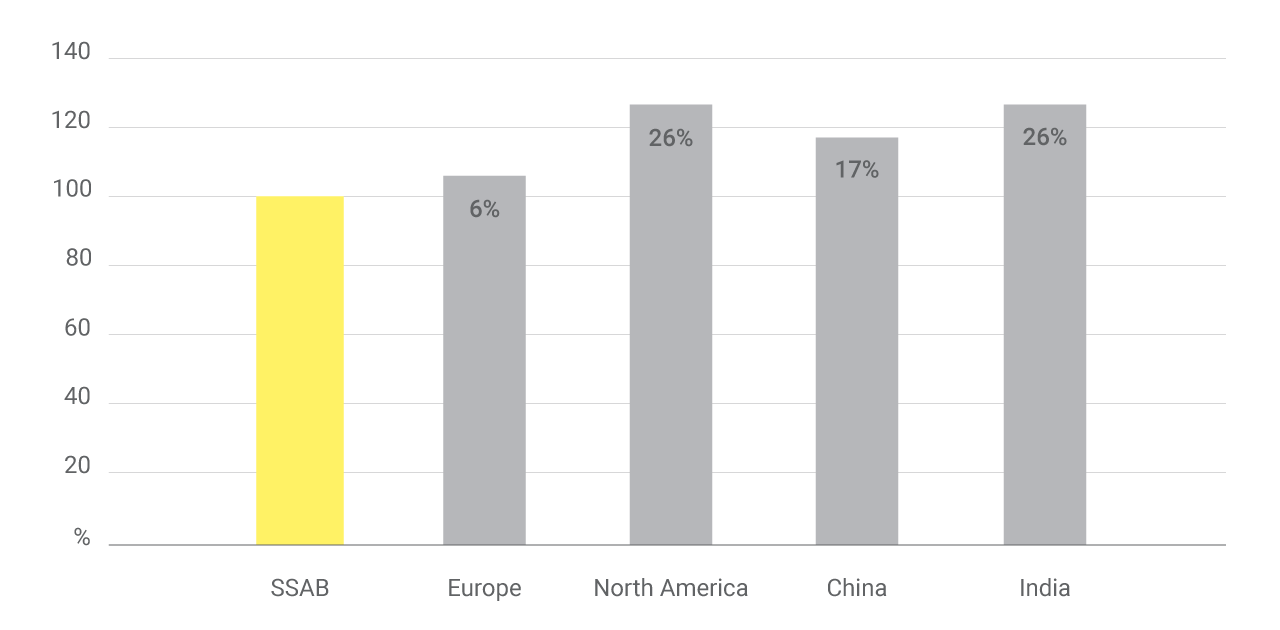

Choosing AHSS steel for lightweighting, strength and safety is a major first step. But you can further reduce your car’s embedded carbon by choosing one of the most CO2-efficient, iron ore-based steel producers in the world: SSAB.

Even though SSAB’s steel production is already highly carbon efficient, we want to make it more so. By as early as 2025, we will further reduce our Swedish CO2 emissions by 25% by starting to convert our blast furnaces to electric arc furnaces.

Our ultimate goal is to totally replace coal and coke (carbon) with hydrogen as the reducing agent in a process with only water vapor as the byproduct.

Our Hybrit project aims to provide fossil-free steel production by 2045. Now that’s future-proofed sustainability for your zero carbon cars!

Source: thinkstep, BF GWP benchmarking, 2019, and SSAB EPD data.

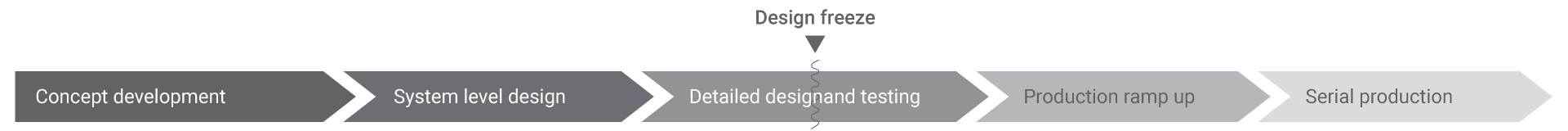

New steel grades with high formability allow for clever design and production efficiency.

Safety regulators keep raising the strength specifications on key safety components in cars — just as you’re trying to lightweight your vehicles. Fortunately, Docol uses the industry’s most advanced computer modeling to help your determine, with great accuracy, the strength of component designs that use thinner gauge AHSS steels.

As you employ more complex geometries to make your parts stronger with less material, we will help you select AHSS steel grades for your trial testing based on local formability, sheared-edge quality, hole expansion ratios, and other key criteria for your designs.

Docol’s fabrication experts work closely with our material selection specialists to address your very specific AHSS forming considerations. For example, edge ductility has a profound effect on the risk of micro-cracks, burrs…and even parts failure. How to weld our advanced high-strength steels is another key consideration we can help with.

By getting Docol involved early in your design process, we can help avoid expensive and unnecessary problems (scrap, downtime, recalls) later on.

Your production engineers want to use AHSS cold-forming whenever they can: it saves energy, increases production line flexibility, and eliminates extra steps, such as heating of components and laser cutting.

Docol has a wide range of advanced high-strength steels appropriate for your cold-forming production goals.

Material consistency will improve output and save money.

Making your AHSS auto parts thinner will save you material (costs) and weight, but it will also demand tighter tolerances, including uniform thicknesses and high overall material quality. The good news is that those same tight tolerances will enable true-to-form final AHSS car components that are more precise and easier to assemble — especially for robotic assembly.

SSAB always produces the same advanced high-strength Docol steel grades (e.g., martensitic, dual phase, etc.) at the same mill. So our AHSS steels are inherently more consistent, making your auto part fabrication and automated assembly more consistent.

It’s no wonder that almost all auto OEMs specify Docol® advanced high-strength steels.

Material-related problems can kill your production uptime while producing expensive scrap.

With each grade always processed at the same plant, Docol delivers exceptionally consistent, high-quality AHSS steels.

Tomorrow's car users will ask for life cycle values.

In the future, cars will be lighter, electric, autonomous and shared. Imagine the near-future driverless taxi or delivery van that runs 24/7, only stopping to recharge or get its next assignment. The intensity of vehicle use could be many times that of today’s cars. What will intense car use mean for automotive material selection?

The intensive use of shared vehicles will encourage auto designers to further expand their application of AHSS steels for lightweighting, strength and safety.

And it’s already happening: the percentage of AHSS steel in cars continues to rise each year.

New challenges, such as protecting the EV’s battery pack, are being met with innovative, sophisticated, and very strong designs using AHSS steels. Docol stands ready to help you meet your future needs head-on with advanced, high-strength steel solutions.

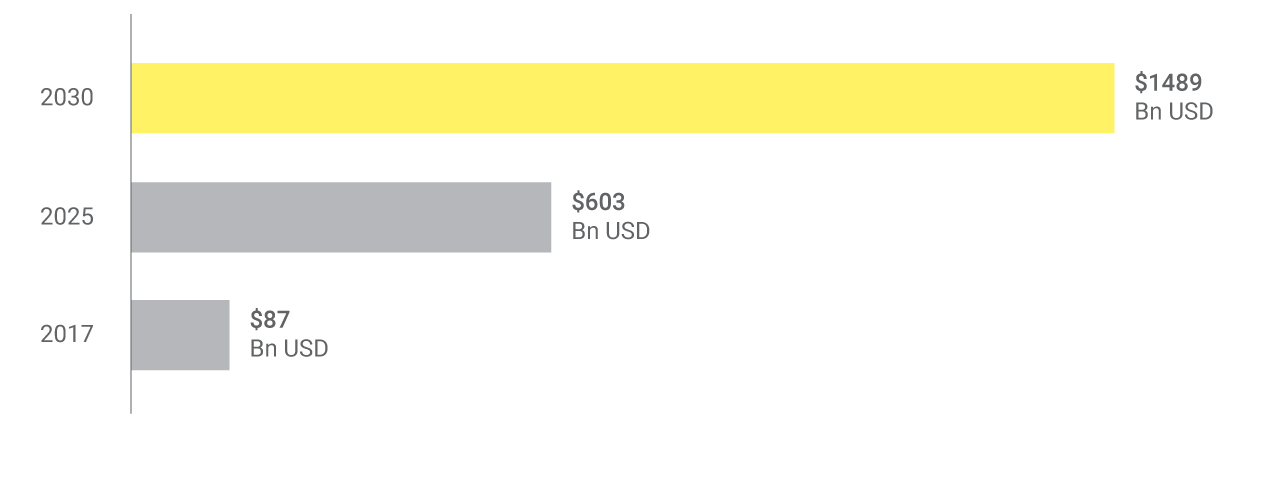

Source: PwC and Strategy, 2017.

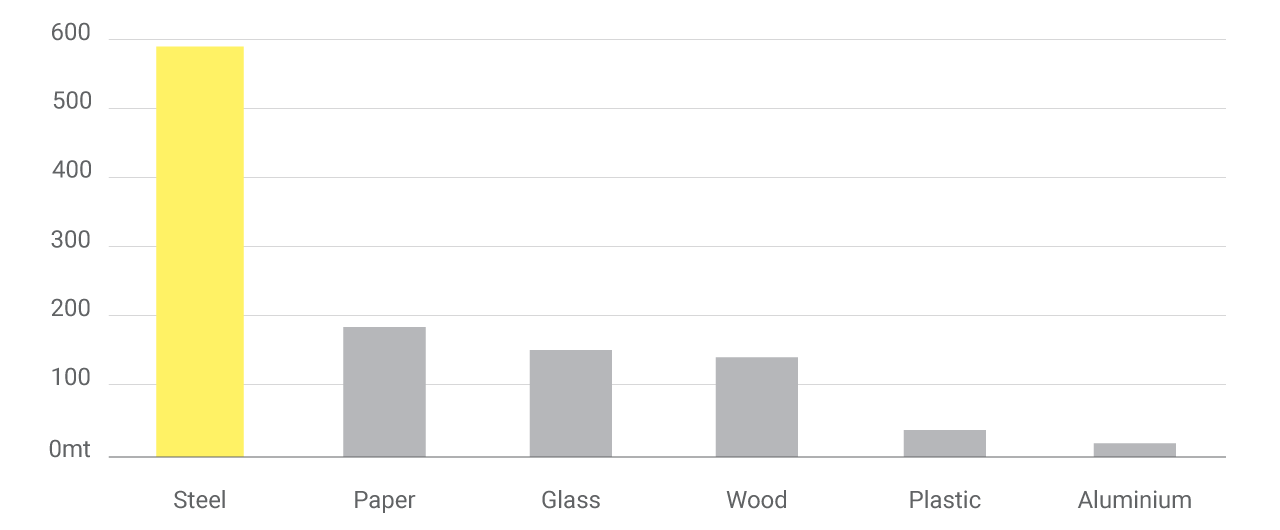

No matter how strong or sophisticated we make our AHSS steel, it’s still 100% recyclable.

In fact, steel is infinitely recyclable, never losing its inherent properties. It’s no surprise that steel is — by far — the most recycled material in the world. And that there will always be an eager market for recycled steel.

So as countries begin to regulate the recyclability content of cars, feel confident as you specify Docol® AHSS steels — light, strong, and sustainable — to maximize your car designs and production.

Source: Worldsteel 2012, Recycling of industrial materials in 2010.