Will all types of SSAB products be available as fossil-free steels in 2026?

Yes.

Will there be a specific certificate for fossil-free steels?

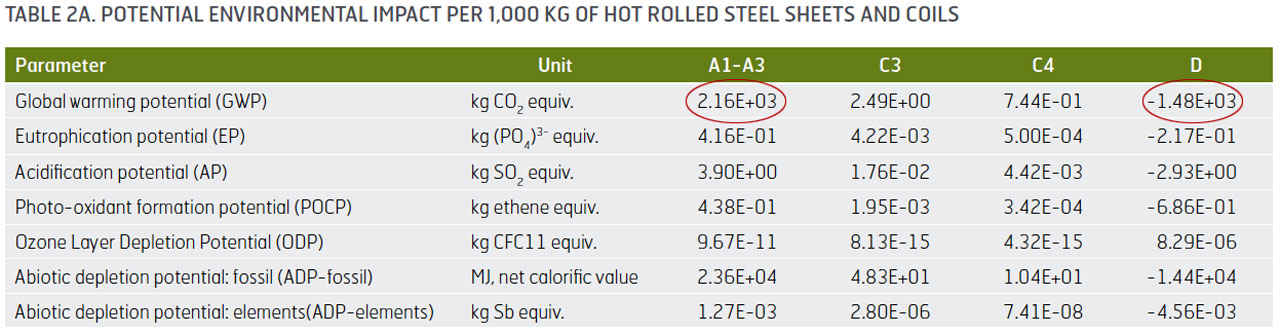

Yes. Fossil-free steels will have their own environmental product declarations.

Will the properties of fossil-free steels be different from traditional steels?

No. The H2 direct reduction ironmaking process produces “sponge iron,” which is fed into an EAF. All of the subsequent steelmaking processes, which produce a specific steel grade’s properties, will be the same as today. The only difference will be that SSAB will run those steelmaking processes using fossil-free fuels and fossil-free electricity.

Is the recycling of fossil-free steel different than traditional steel?

The recycling process is the same. However, fossil-free steel will — for the first time ever — increase the amount of steel scrap available, worldwide, without causing significant CO2 emissions. That is a big difference.

How is the CO2 footprint certified for the upstream products you use?

We have a third-party verifier go through the materials and confirm the material databases we have used. That’s all part of the EPD verification process and all of the steps are transparent to everyone.

With the hydrogen direct reduction process, is SSAB concerned about hydrogen embrittlement?

We asked that question, too. But the answer is “no.” In the ironmaking process, the hydrogen (H2) will combine with the oxygen (O) in the iron oxide, forming H2O (water) as a byproduct. Any remaining hydrogen will disappear very quickly, if not before, then most certainly in the electric arc furnace.