Steel Pile News

Threaded RDT270-320 piles in deep Norwegian clay

February 23, 2021 9:38 CET 6 min read

Our threaded pile design for easy installation, saw the “first light” in 2011 and became a huge success, especially in Norway and Sweden. In 2019 SSAB’s changed the thread profile to enhance the installation speed further. It also made the logistics on site easier because the splice covered all wall thicknesses and steel grades for one dimension. The portfolio was also extended to include RD270 and RD320 with loose sleeves. SSAB provides now piles with threaded splice from RD90 to RD320 and the new name is RDT and RDTs for S550J2H.

Last year in Sandefjord, Norway SSAB’s first big project for splices on the new dimension RDT270 and RDT320 became a reality. It demanded 348ton and 3665m of threaded piles. HENT AS, one of Norway’s biggest entrepreneurs was the contractor and Sør Norsk Boring AS was the piling contractor. Sør Norsk Boring AS is owned by Aarsleff. The building was 5 story’s high and had a total of 7500m2. It was planned to contain 40 care homes, service providers, 10 private apartments and 2200m2 commercial real estate.

Illustration on how the new building will look like (from Bolig Norge)

The ground conditions in Sandefjord is heavily influenced by marine sediments since the entire area was covered by the sea after the last ice cover retreat for 11600 years ago. A typical log shows moraine over bedrock with clay interval in the middle and sand and silt on top. The clay interval has potential to be “quick”. In the particular project site the depth to rock was 64-89m demanding piles up to 90m long.

In total 56 piles was installed, 52 of them where end bearing and 4 tensile piles. Sør Norsk Boring AS use 6m elements. Due to the soft soil conditions the piles where flushed through the clay down to moraine and drilled further into rock.

Pictures from site (Sondre Smeland - SSAB)

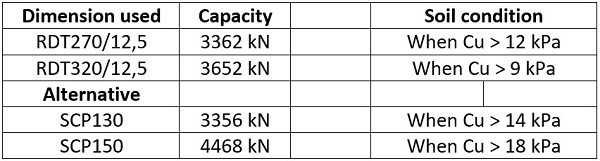

In Norway the concept of using RDT piles is often an alternative to steelcore piles:

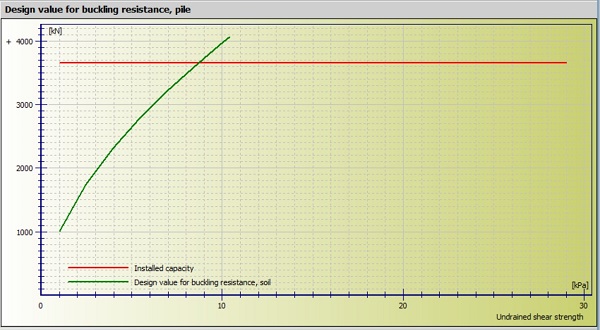

Graph form SSAB’s software RRPilecalc showing design value of the pile compared with installed capacity and buckling resistance related to Cu.

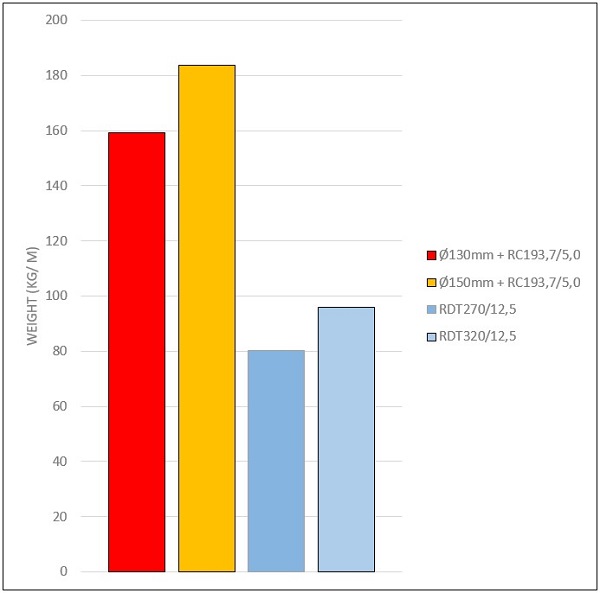

In most cases RDT piles are much easier and faster to install compare to steelcore piles. It is limited to one operation; drilling the pile to rock. While steelcore piles demands drilling of the casing tube, installation of the steelcore pile and grouting of the annulus. The overall weight is lower for RDT piles. This gives easier and less transportation and logistics on site. Due to this both the environmental impact and the overall cost of pile installation proves better in many cases with RDT piles compared to steelcore piles.

Graph showing the weight per m of pile per pile type and pile dimension.

The foreman on the project in Sandefjord stated the following; "Happy with old splice – very happy with new splice, it worked excellent! Wished there was much more RDT & also RR pile project in Norway. Steelcore piles has too much focus"