Articles

Savings by replacing larger RR® piles with RRs220/10 piles in major hospital building project for Central Finland Health Care District

December 12, 2016 8:00 CET 6 min read

SSAB launched new RRs220/10 pile size last spring to widen SSAB’s high-strength steel RRs® pile selection. This new pile size enabled cost-efficient alternative design solution for new hospital building project. New hospital will be part of Central Finland Health Care District (KSSHP), which is the largest non-university hospital district in Finland. The district is populated by 250 000 people. New hospital is built in Kukkumäki, Jyväskylä. Total area of the hospital is 100 000 brm2. Building project will continue until 2020 and total cost estimation is 398,5 million euros.

Figure 1. Central Finland Health Care District is building new hospital in Jyväskylä.

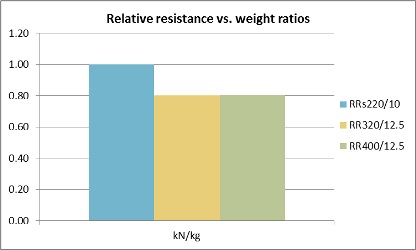

Original design of the project included significant amount of RR400/12.5 and RR320/12.5 piles. Those were replaced mostly by RRs220/10 due to material savings realized by stronger steel grade and better resistance-weight ratio. As shown in Figure 2, the material savings can be up to 20 % due to use of high-strength steel in piling. In addition to that the alternative solution enabled use of pile elements which resulted in time savings when splicing is easier and faster compared to splice welding. Also material waste is minimized when leftover piece can be utilized in next pile.

Figure 2. Comparison of relative design resistance [kN] vs. weight of pile pile [kg/m] ratios of different pile sizes.

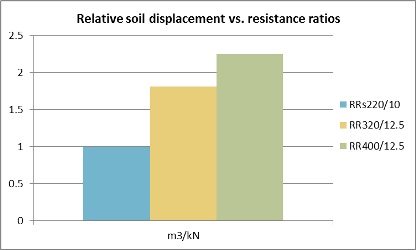

Alternative solution with smaller diameter piles means also less displacement and disturbance of soil in relation to the load-bearing capacity of the pile. When comparing RRs220/10 and RR400/12.5 pile sizes, similar design resistance is achieved with clearly smaller soil displacement. Figure 3 shows relative soil displacement – resistance ratios for three different pile sizes.

Figure 3. Comparison of relative soil displacement [m3] vs. design resistance [kN] ratios of different pile sizes.

Total project delivery includes 18 000 meters of RRs220/10, 2 113 piles and 3 300 meters of RR170/10, 380 piles. Piling contractor is Kantolan Paalutus Oy. Piling work is realized in two phases; first phase is done during November-December including 60% of the piling and second phase will be done next year during March-April. During the first phase, pile deliveries have been reliable and accurate. Site manager Henri Laitila has been satisfied with the fluency of the deliveries. “Pile deliveries have been able to be synchronized with the progress of the piling so that there have been no need for big intermediate storages at the job site”, he says.

Figure 4. Pile deliveries and piling have been synchronized to avoid the need for intermediate stocks at the job site. Waste has been minimized by using pile elements.

Kantolan Paalutus Oy has two piling rigs at the job site. Piling has gone according to contractor’s expectations and time schedule. Pile lengths have corresponded quite accurately with the expected lengths based on soil investigation. Pile lengths have varied between 1.5 to 13.0 meters. Soil base is sandy and partly rocky, but it has not caused any problems like compaction.

Figure 5. Soil base is mainly sandy silt and partly rocky, but it has not caused any problems like compaction.