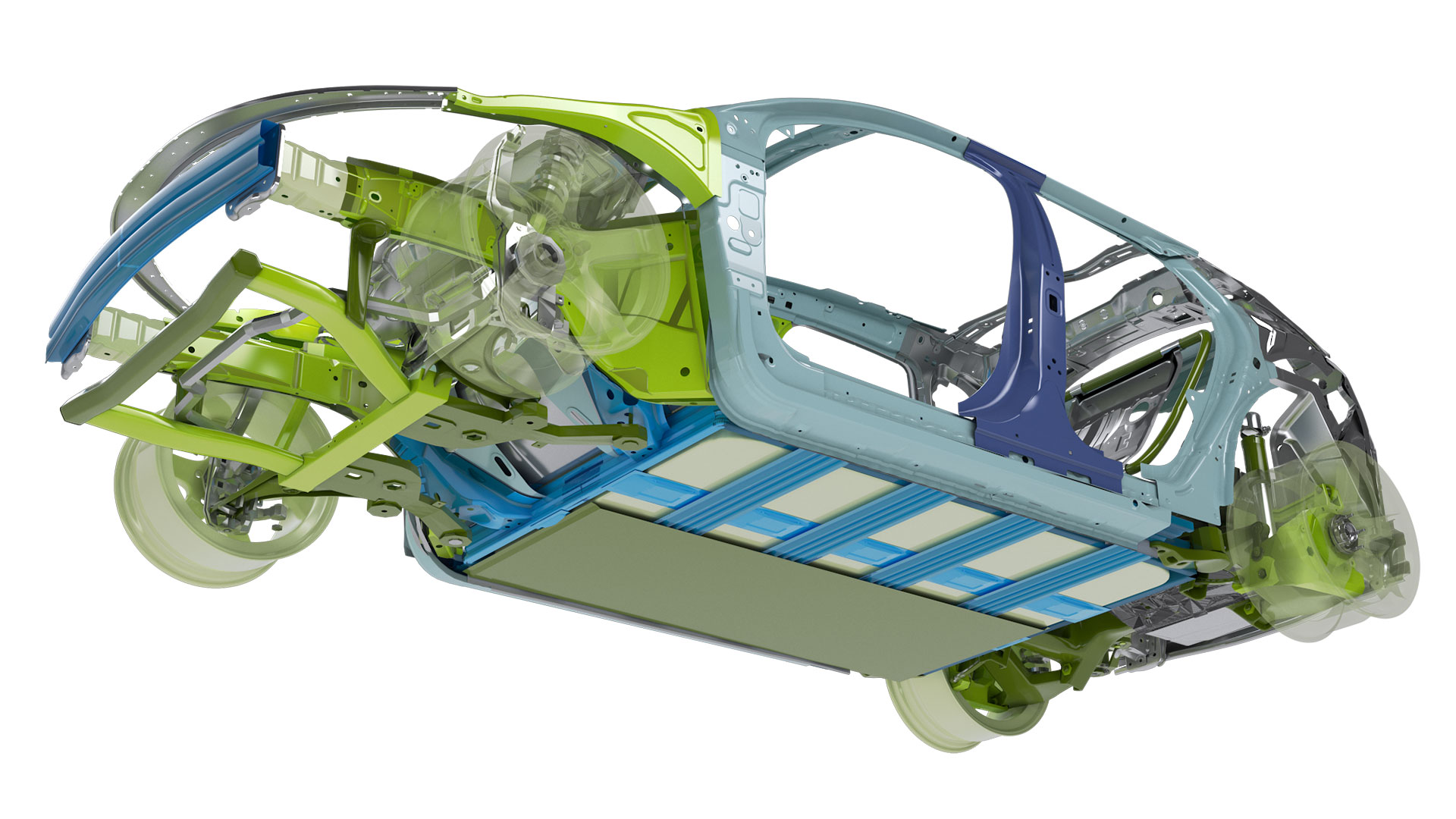

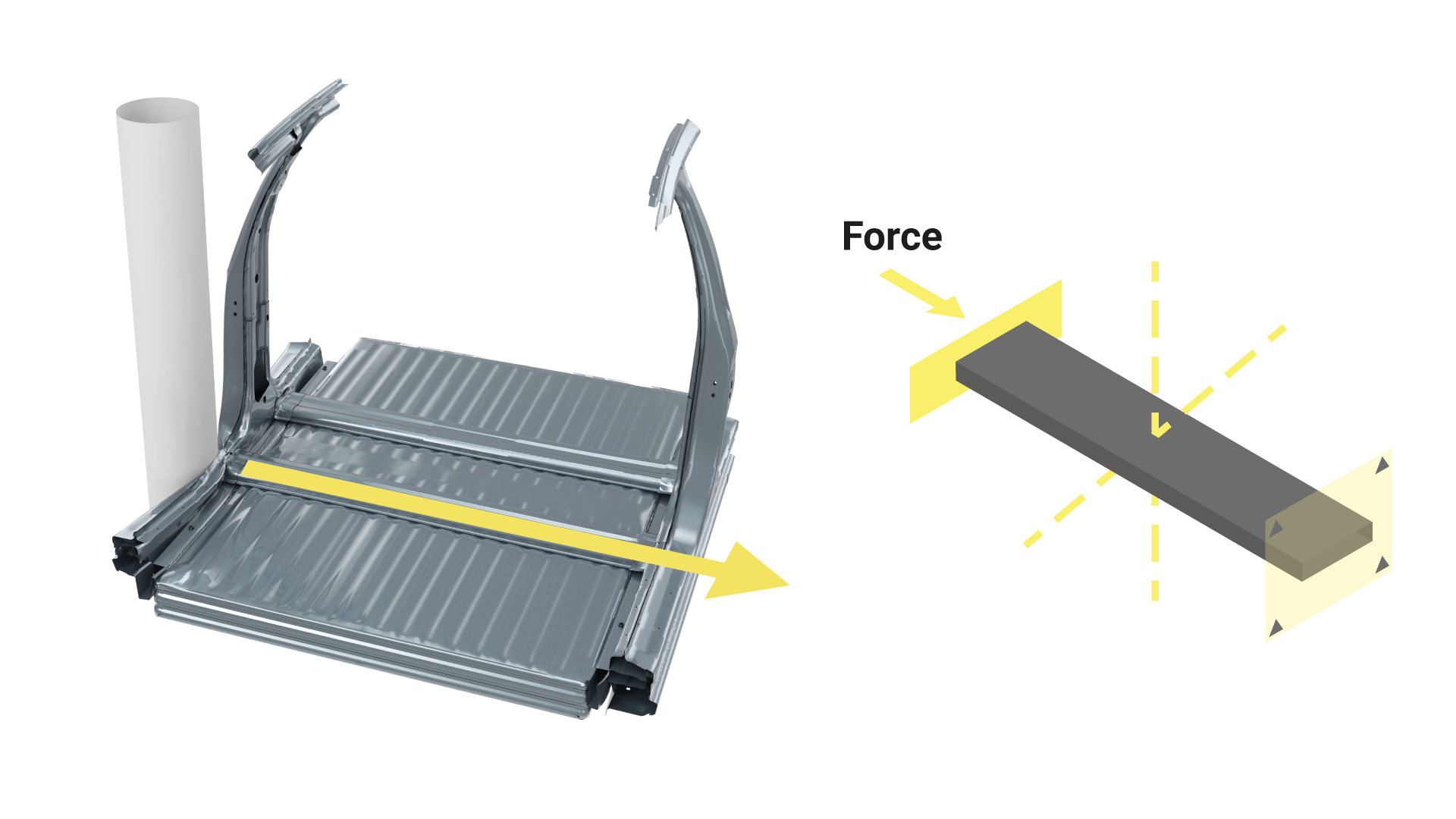

Unlike a car with an internal combustion engine, an EV must absorb more energy through the car’s sill. Why? 1) The weight of the EV’s battery, 2) the EV’s stiffer underbody, and 3) the requirement that no intrusion whatsoever is allowed into the EV’s battery pack. Extruded aluminum in the sill has been seen as an efficient way of absorbing higher energy levels, but at a price premium.

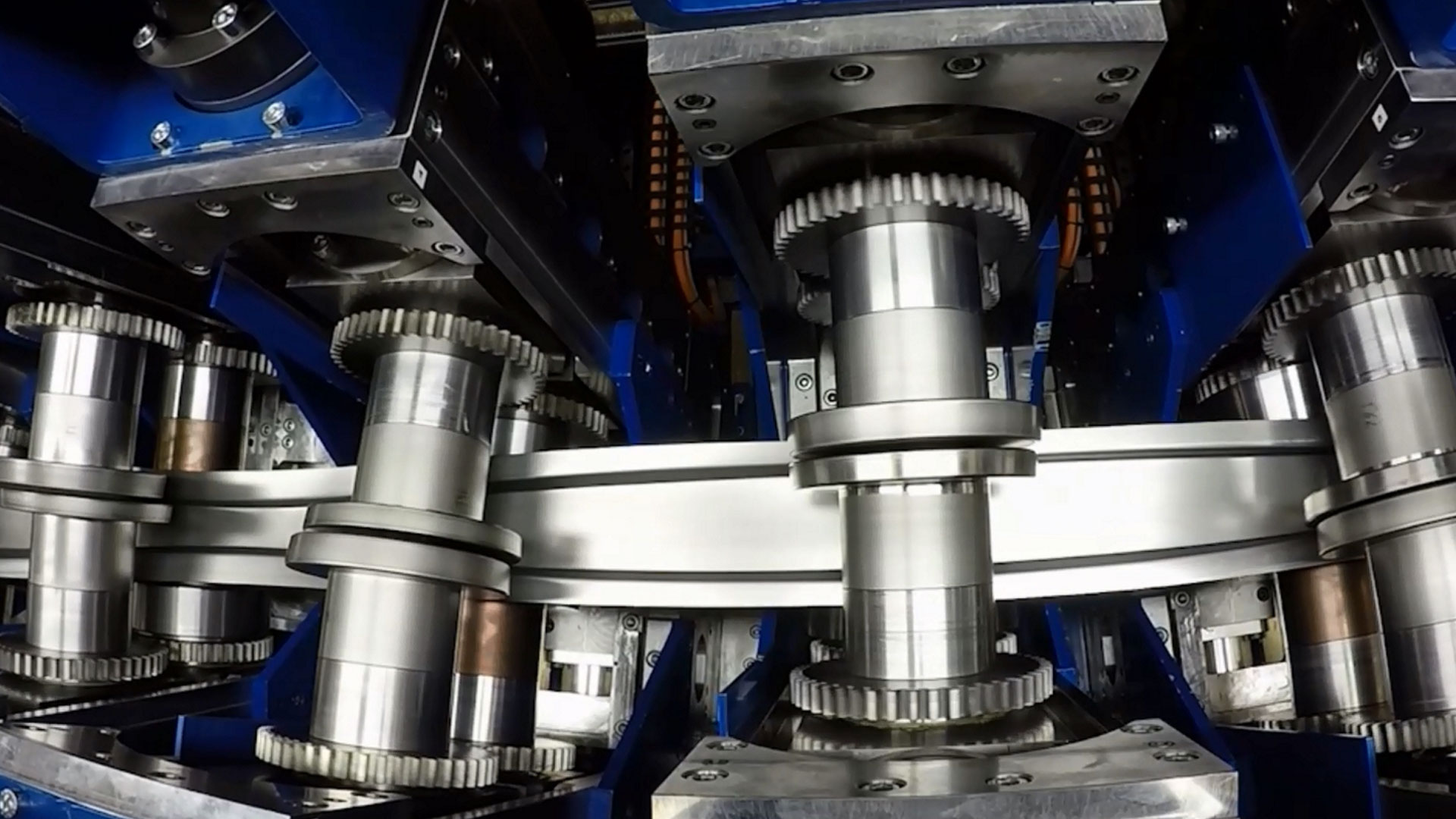

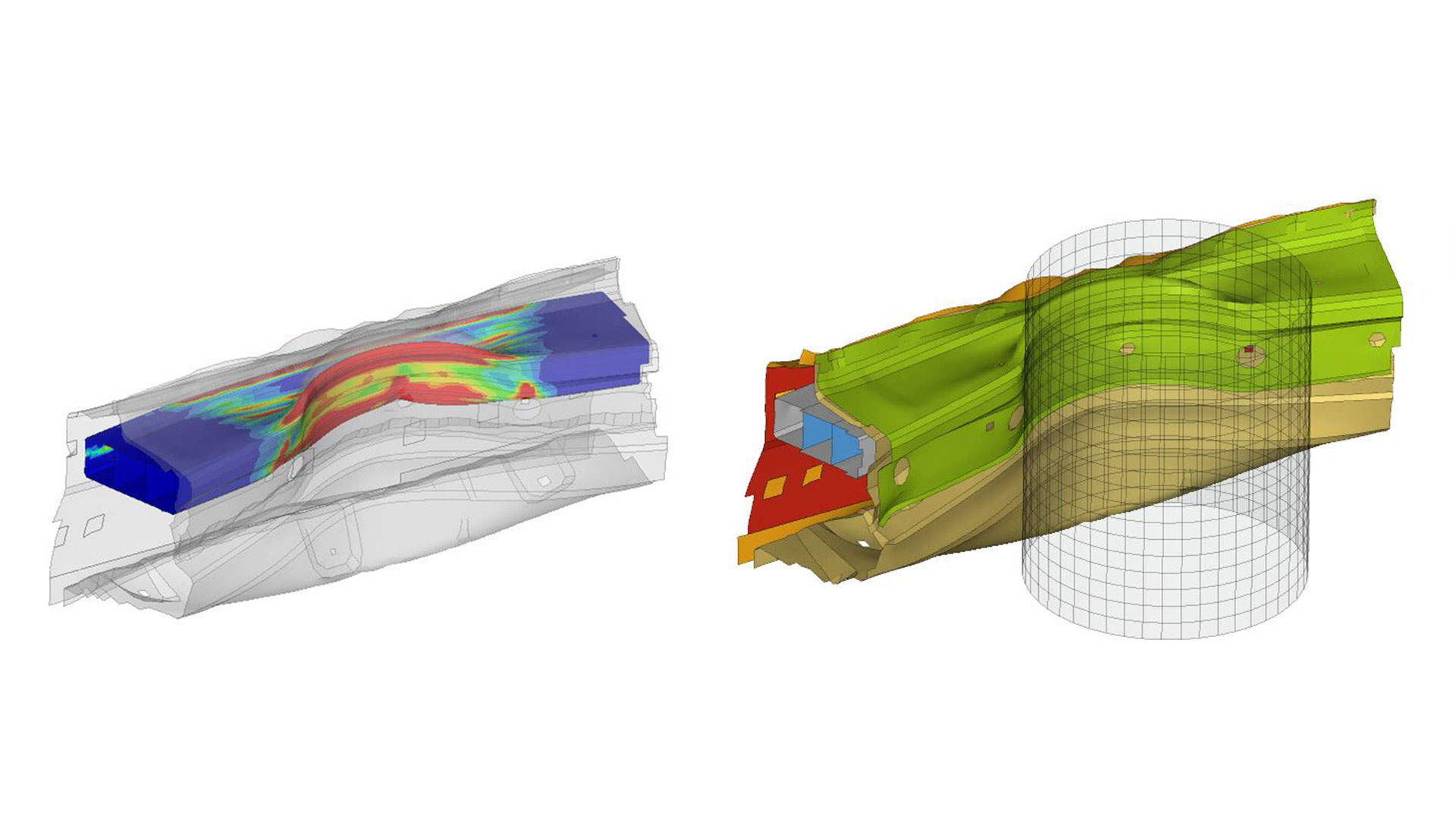

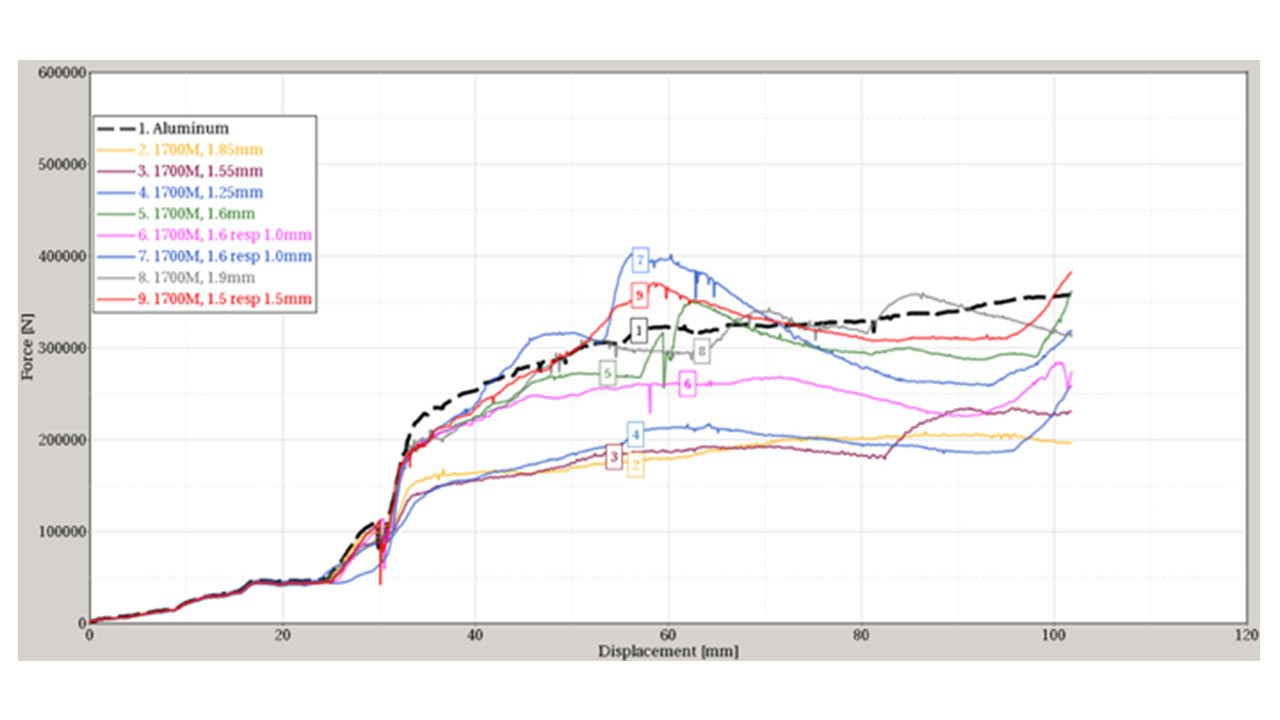

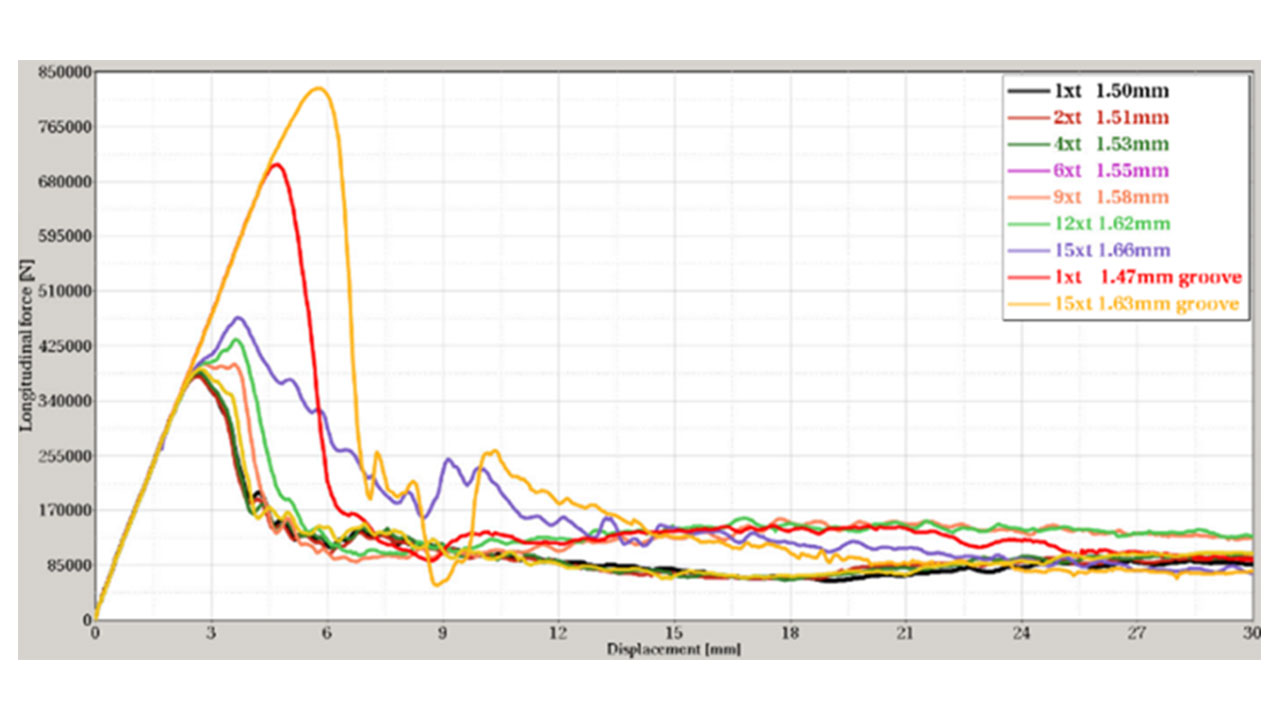

To try match the performance of extruded aluminum sill beams, SSAB has run simulations for 2D roll-formed sill beams made from Docol CR 1700M steel. The extruded aluminum alloy is EN AW-6082 T6, with a thickness of 4.5mm for the outer walls and 3mm for its ribs.

The number of possible designs for 2D roll forming the sill beams are endless, so the results in Figure 6 only show some of the typical designs. (Many more sill beam profiles have been simulated by SSAB but are not shown here.)