ST100XF

Download data sheet

Download data sheet

ST100XF steel plate is a low-carbon, thermo-mechanical controlled-rolled material with a guaranteed toughness that has been developed for applications where increased strength-to-weight ratios are required. ST100XF is available as temper-leveled, cut-to-length plate and meets or exceeds the requirements of ASTM A656 Grade 100.

Applications

ST100XF plate is designed to be used for transport trailers, construction equipment, crane booms, mobile manlifts, agriculture equipment, rail cars, heavy vehicle frames and chassis.

| Grade | Product type | Thickness (in) |

Width (in) |

Length (in) |

|---|---|---|---|---|

| ST100XF | Temper Leveled Plate | 0.188 - 0.375 | 60 - 96 | 72 - 720 |

| ST100XF | Temper Leveled Plate | 0.375 - 0.500 | 60 - 72 | 72 - 720 |

SSAB's Cut-To-Length facilities use the temper leveled coil (TLC) process to produce temper leveled plate products. For additional information concerning our temper leveling process, please refer to our SSAB Americas: North American Cut-to-Length Operations.

Inquire for Coils for Conversion To.

Tensile testing is performed using plate-type tensile specimens in the transverse direction according to ASTM A6 requirements. The minimum requirements are tabulated below:

| Product type | UTS (ksi) | Elongation in 2" 1) (min %) |

Min average energy at -40 °F(ft-lb) 2) |

|---|---|---|---|

| Plate | 110 | 16 | 20 |

NOTE: Inquire for other test specimen orientation, minimum energy requirements, and/or test temperatures.

1) Additional elongation requirement adjustments are allowed per the Tension Test section of ASTM A6.

2) Longitudinal specimen orientation. For sub-size CVN specimens, the minimum average energy is reduced proportionally in accordance with ASTM A673.

(Heat analysis, wt. %)

| C (max %) |

Mn (max %) |

P (max %) |

S (max %) |

Si (max %) |

Al (max %) |

Cb (max %) |

V (max %) |

Mo (max %) |

N (max %) |

Cb+V+Ti (max %) |

Ti (max %) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.10 | 2.00 | 0.025 | 0.006 | 0.40 | 0.06 | 0.10 | 0.15 | 0.50 | 0.020 | 0.20 | 0.03 |

| Thickness (in) | 0.188 - 0.500 |

|---|---|

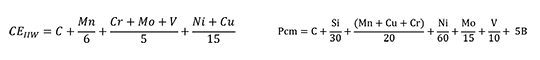

| Pcm (typ wt %) | 0.21 |

| Typical CEV (wt %) | 0.51 |

Thickness, width, and length tolerances for ST100XF steel plate are in accordance with the requirements of ASTM A6. The flatness tolerance for as-supplied plate is ASTM A6 half-standard flatness. Procedures and tolerances for all other testing shall be in accordance with ASTM A6.

ST100XF exhibits cold forming characteristics similar to those of ASTM A656 Grade 80 and Grade 100. The minimum recommended punch radius, R, and the die width opening, W, as a function of bending orientation for cold bending are provided in the following table:

| Thickness(in. [mm]) | Bend Axis Perpendicular to Rolling Direction Inside Radius, R (min.) | Bend Axis Perpendicular to Rolling Direction Die Width, W (min.) | Bend Axis Parallel to Rolling Direction Inside Radius, R (min.) | Bend Axis Parallel to Rolling Direction Die Width, W (min.) |

|---|---|---|---|---|

| 0.188 – 0.500 | 1.75t | 8t | 2.625t | 10t |

ST100XF steel plate is weldable by conventional electric arc welding processes, using low-hydrogen consumables. Although ST100XF has a chemical composition that is readily weldable without preheating or post-weld heat treatment, a precautionary preheat of 120° C (250° F) is recommended to remove any moisture. When matching consumables are not required, lower strength electrodes are recommended.

| Welding process | Consumables |

|---|---|

| Shielded Metal Arc (SMAW) | AWS-E11018 |

| Submerged Arc (SAW) | AWS F11X-EXXX |

| Gas Metal Arc (GMAW) | AWS ER110S-X |

| Flux Cored Arc (FCAW) | AWS E11XT-X |