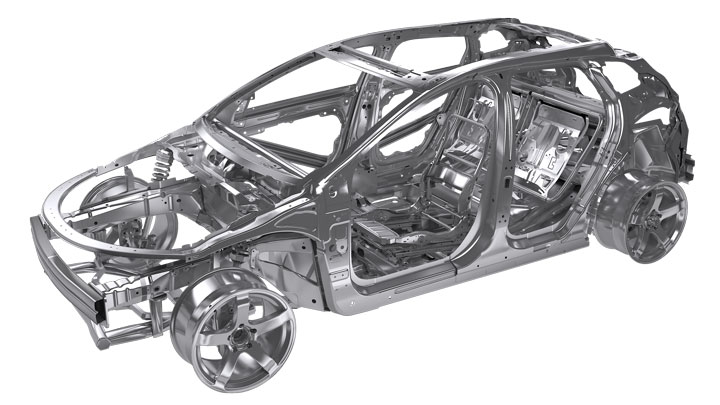

Ultra-High Strength Steels (UHSS): what are they and how they improve vehicles

Ultra-high strength steels (UHSS) in cars are simply advanced high-strength steels (AHSS) with significantly higher minimum tensile strengths. Viewed another way, UHSS (aka “ultra-high tensile steels”) are a subset of the boarder category of AHSS steels.