مصنع SSAB السعودي – الدمام

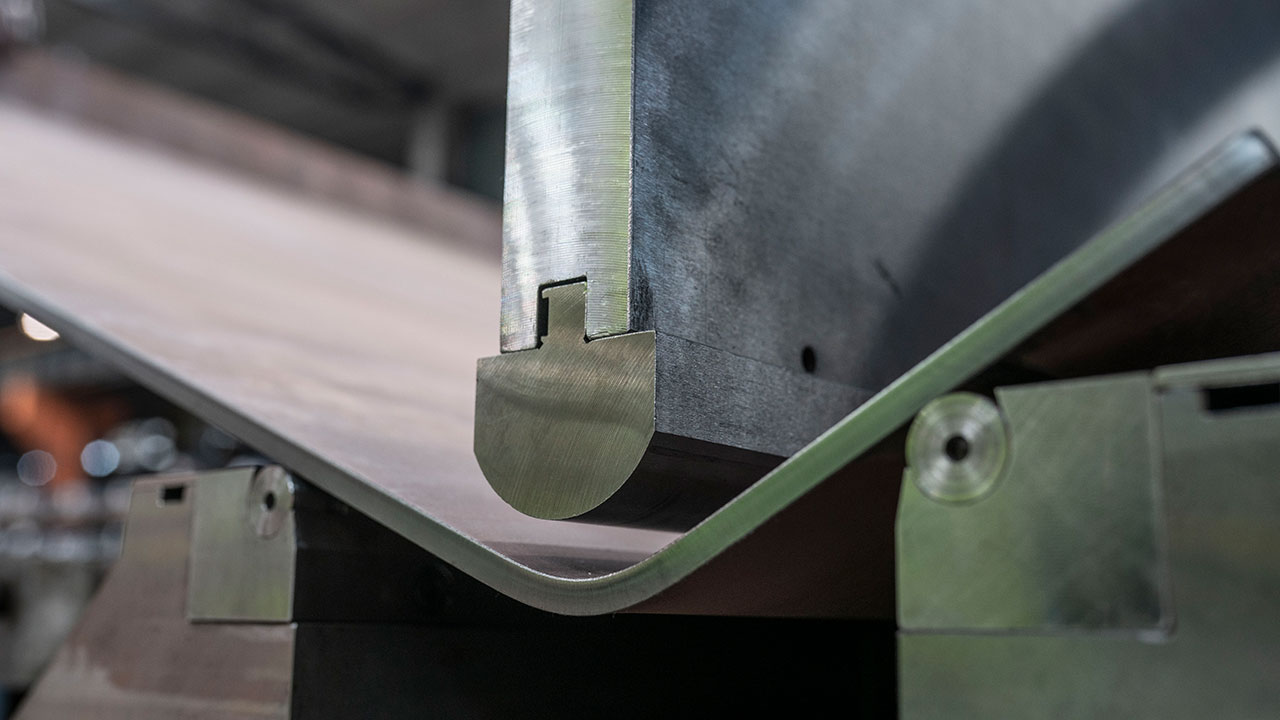

إننا نقوم بإعادة هندسة وتصنيع مكونات تراكب Hardox® Wearparts المقاومة للتآكل ومكونات التراكبِ Duroxite® المستخدمة في الصناعات الثقيلة التي تتطلب مكونات مقاومة للاحتكاك والتآكل طويلة الأمد. إن عمليات الترقية والإصلاح التي نجريها - سواء في مصنعنا أو في موقعك - يمكن أن تجعل المكونات تدوم أطول من مكونات شركة تصنيع المعدات الأصلية (OEM) التي تحل محلها إلى حد كبير، مع زيادة سرعة أوقات إنجاز العمل.

طلب عرض أسعار الاتصال بنا